Your cart is currently empty!

Measured Performance

Why is it so important to have efficient atomization?

Smaller aerosol droplets generated translates to quicker cooling and better delivery of the water/methanol mixture. It also means there will be a more homogenous delivery of the mixture when injected upstream of an intake manifold.

How does our nozzle compare to others?

The differences in performance can be easily seen by just spraying one of our nozzles and feeling the cold air, rather than cold mist generated from the system and how much finer the spray pattern is. This can be seen in the video on the left. Looks aren’t enough though, we also measured the differences in performance in both controlled and real life conditions.

Intake Air Simulation Rig

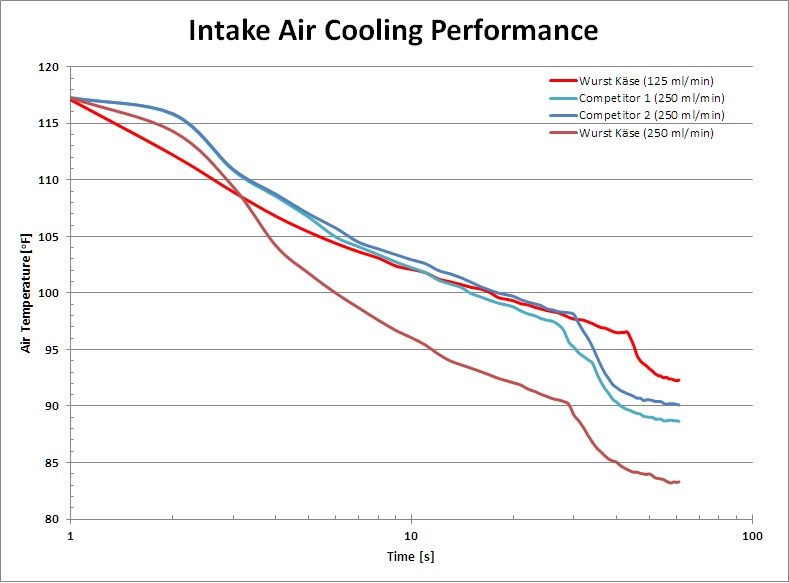

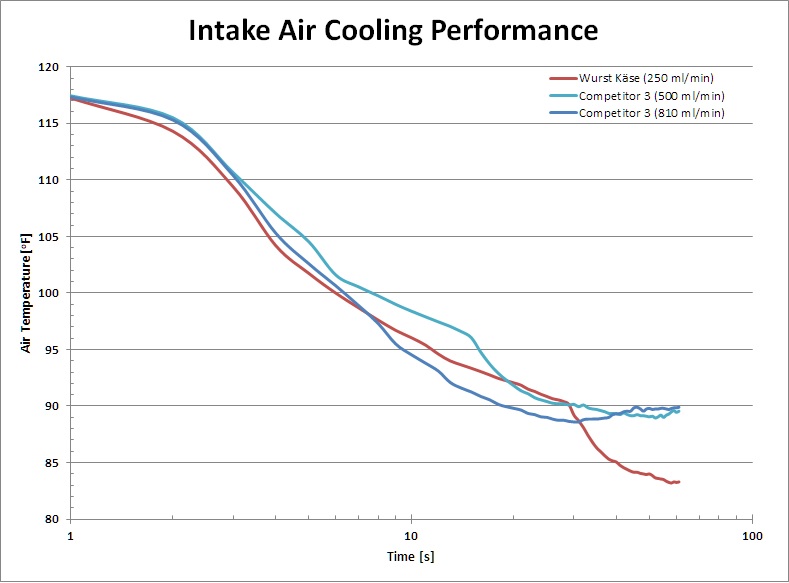

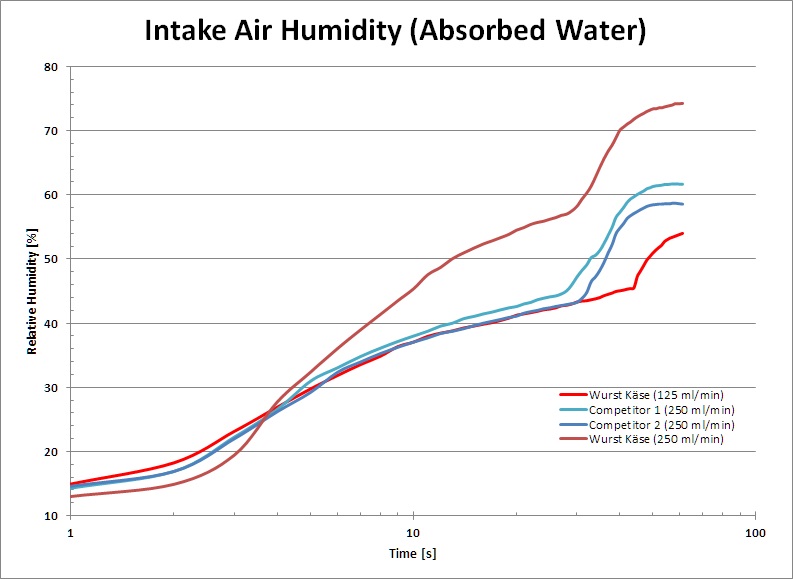

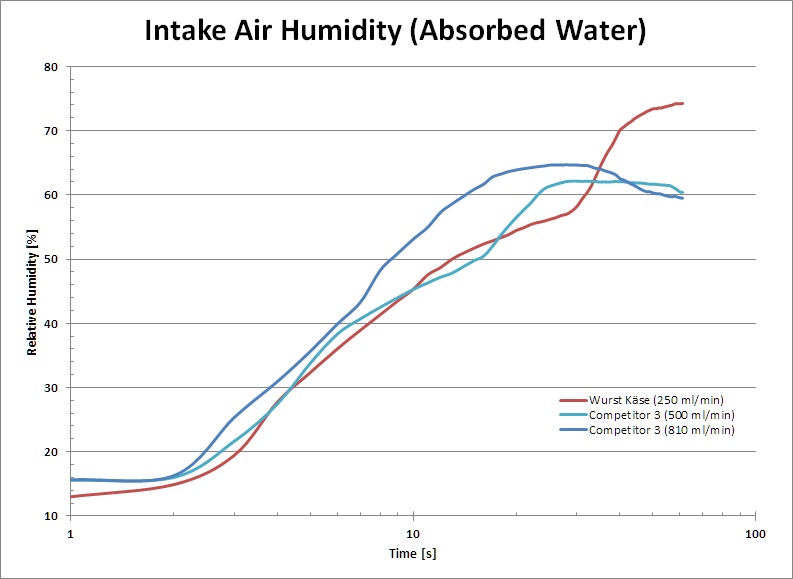

We designed a test rig to compare our nozzles directly to competitors. It measures Air Velocity/Air Flow, Air Temperature, and Humidity. A series of tests were conducted to measure the differences in performance as compared to other nozzle systems currently available.

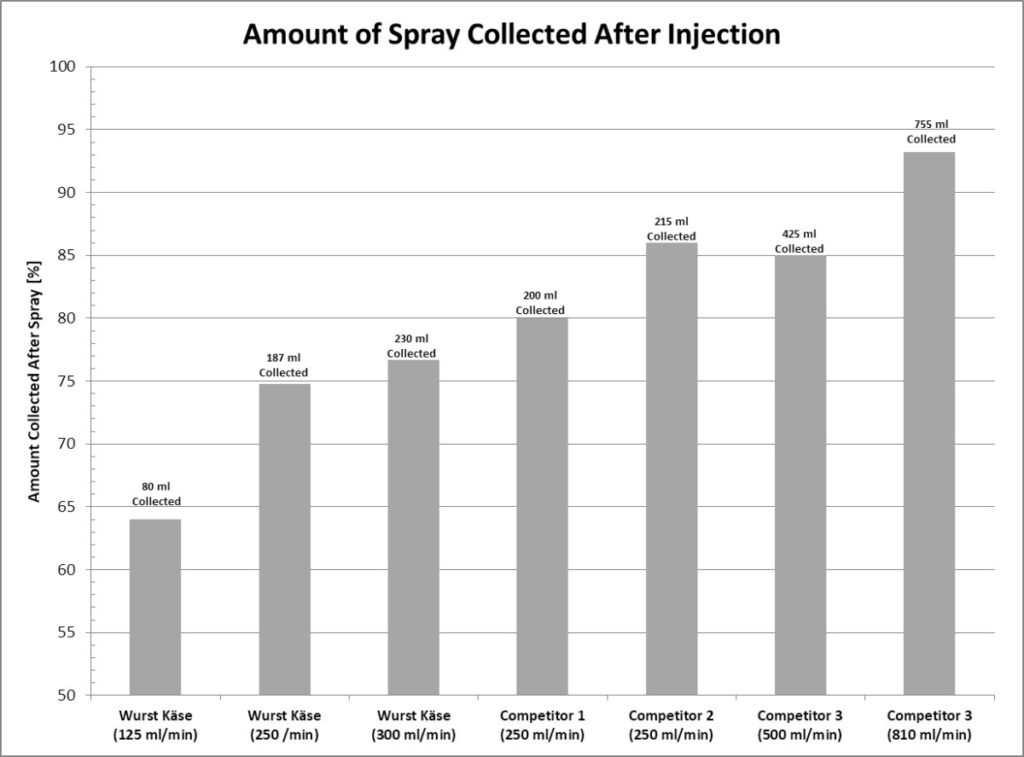

Our nozzle shows amazing performance at all flow ranges and injection points. As shown below the cooling performance was measured to be about twice as good as traditional nozzles at similar flows. During testing the amount of wasted fluid collected measured up to 20% less.

The amount of absorbed thermal energy and ability for methanol to be well distributed for efficient combustion is demonstrated by the increase in humidity. Having the ability to atomize water/methanol to smaller droplets allows for more efficient use of the methanol mixture delivered.

Real Life Data Logs

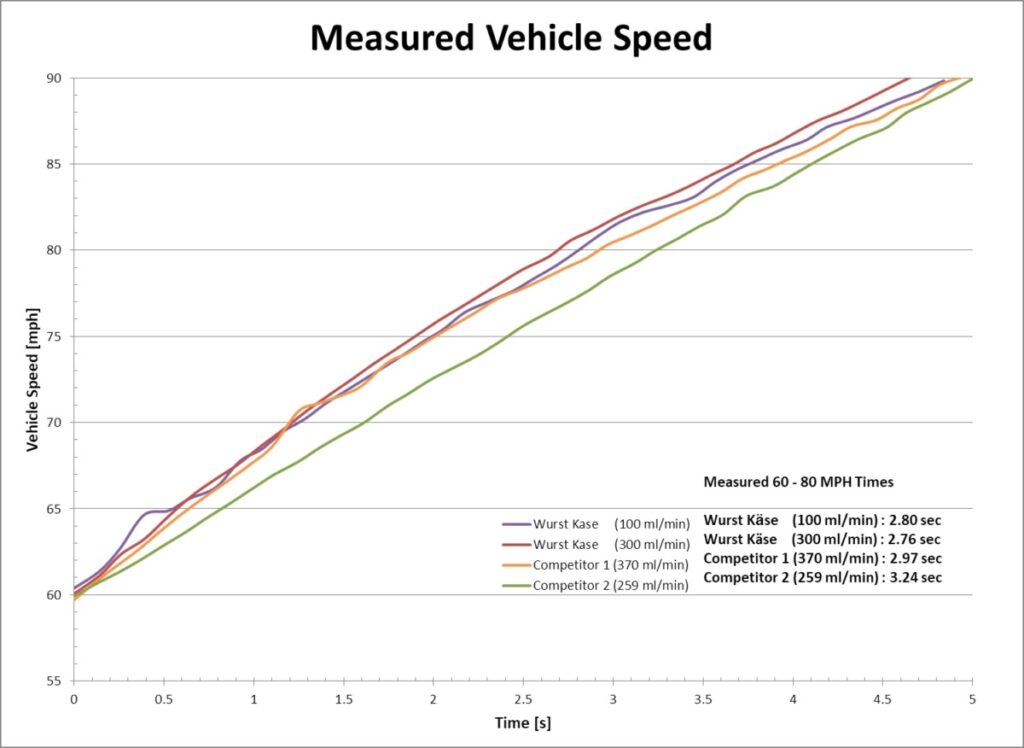

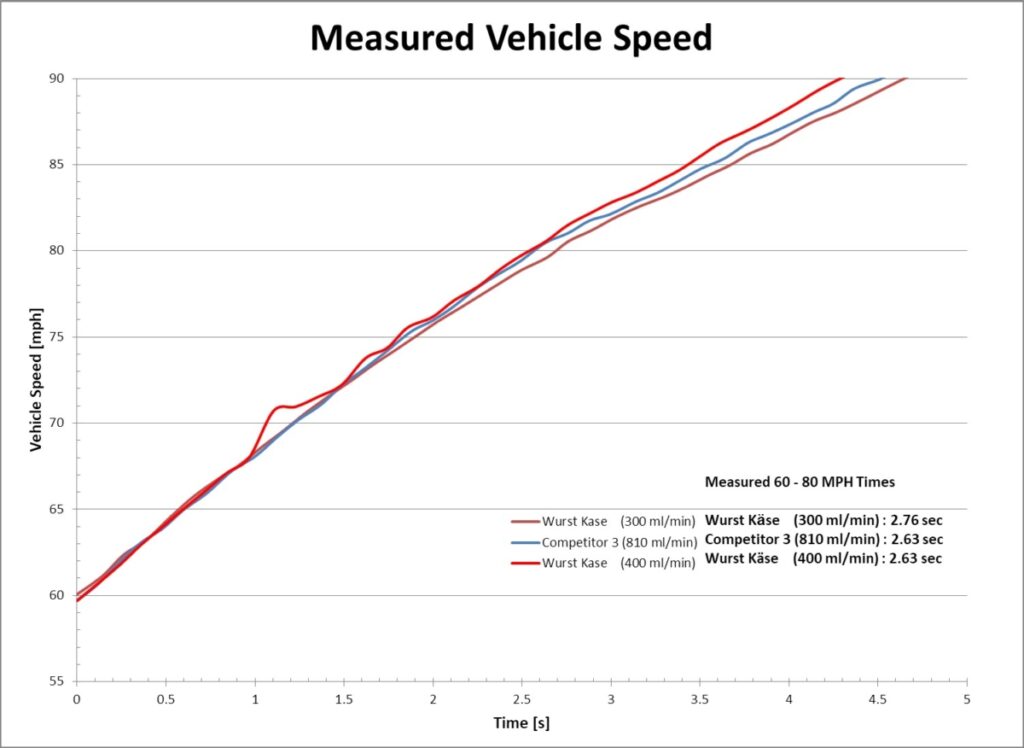

We didn’t stop at test bench performance, we also measured the differences in real life from data logs. All data collected was run with similar fuel and a 50/50 mix of water methanol on the same track. Data was collected via a Cobb V3 Access port measuring the data directly from the car’s OEM sensors.

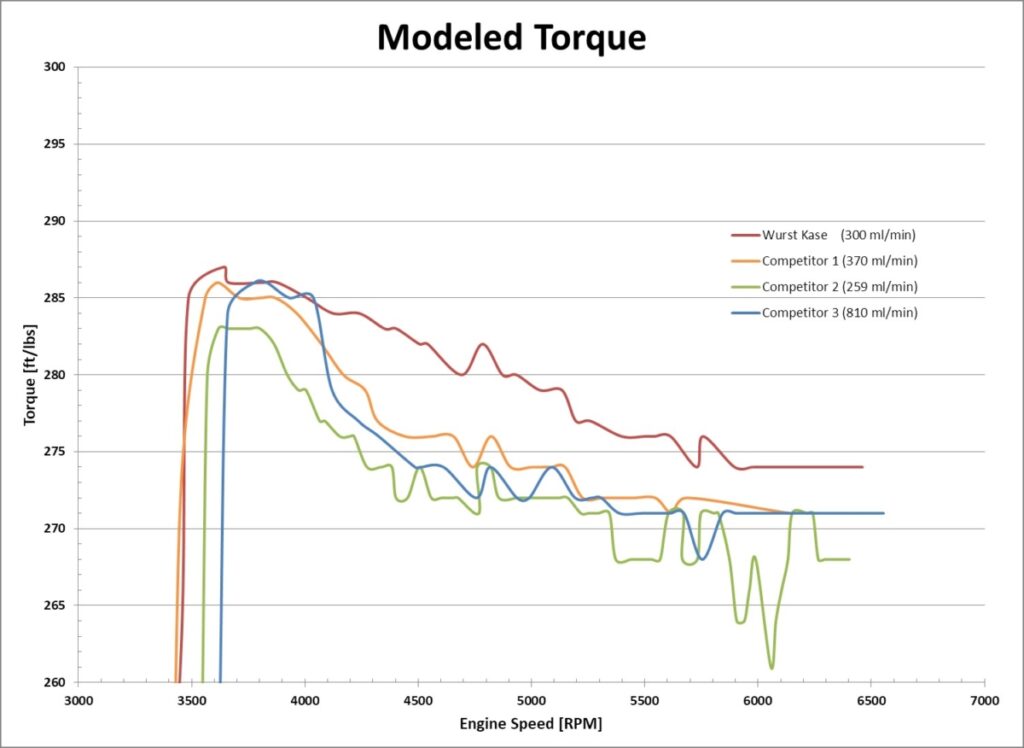

In real life the Wurst Käse methanol injection kit is able to deliver similar performance while delivering up to 50% of the volume. Vehicle speeds of full throttle runs measured with different nozzles as well as some other useful graphs can be seen below.

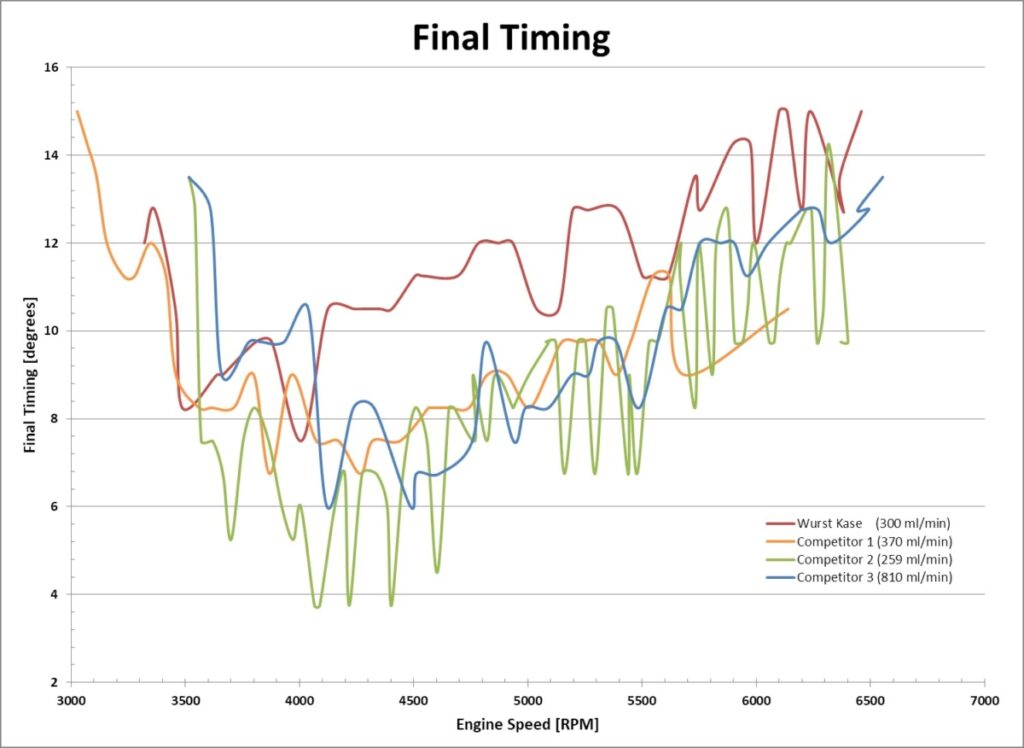

Since the GTI uses a computer controlled variable timing system, the differences in available performance can be compared using Final Timing (or Ignition Timing). Having a higher and smoother final timing means the engine is working in a comfortable range and not trying to make sudden adjustments. This allows for more consistent delivery of torque!

Science Meets Performance is our slogan for a reason!